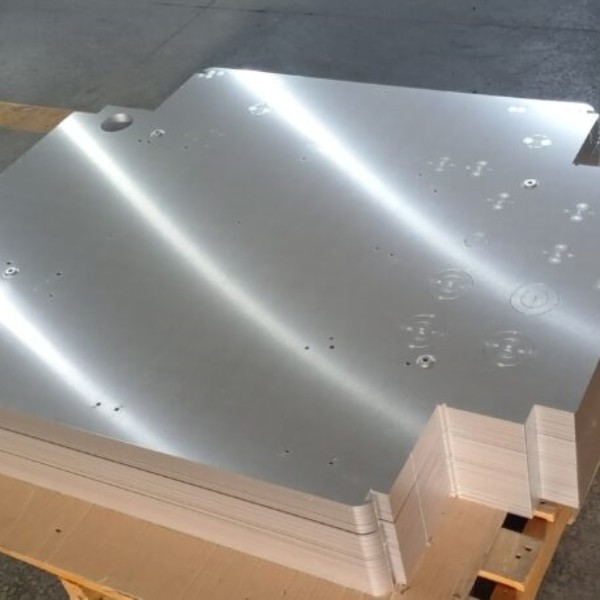

What should Pay Attention to Aluminum Sheet Processing?

Aluminum sheet is simple to crack after bending, or perhaps burst after bending through anodic oxidation, so how to not crack it? The following are some of the main causes and precautions for cracking after bending aluminum sheet:

1. Aluminum plate hardness: aluminum plate hardness is too high, it is simple to crack. This requires the selection of good aluminum, mainly depending on the aluminum trademark and condition. Usually 1 series, 3 series, 5 series of comparison commonly used; 6 series, 7 series of hardness is too high, to do annealing treatment to O state before good bending. There is also the quality of the aluminum plate, the same type of aluminum plate imported material than domestic material is not simple to crack, but the price of the material is also a lot more expensive.

2. The thickness of the aluminum plate: too thick aluminum plate is not good bending, try to use a thin aluminum plate.

3. Bending R angle size: the larger the bending R angle, the higher the success rate, so try to adjust the bending R angle as large as possible.

4. Aluminum plate texture direction: bending direction should be straight with the aluminum plate texture direction, not parallel.

5. The need to draw the aluminum plate parts, in the case of the process promised the best bending and then pull the shape, otherwise it will add the probability of bending and cracking.

The above aspects of comprehensive treatment, aluminum bending cracking questions will be better dealt with.

Custom Metal Box Manufacturers | Custom Sheet Metal Enclosures | Custom Aluminum Box | Custom Sheet Metal Boxes | Custom Metal Boxes | Sheet Metal Supplier | Steel Box Manufacturers | Sheet Metal Box Manufacturers | Custom Made Metal Boxes | China Sheet Metal Manufacturer | Outdoor Vending Machine Enclosures | Industrial Machine Enclosures | Metal Enclosures for Electronics | EV Charger Outdoor Enclosure | Outdoor EV Charger Enclosure | EV Charger Enclosure | Custom Aluminium Box | Custom Steel Box | Metal Box Supplier | Metal Enclosure Manufacturer | Sheet Metal Enclosure Manufacturers | Metal Enclosure Box Manufacturer | Metal Enclosure Manufacturer | Aluminium Box Manufacturer | Outdoor Equipment Enclosures | Aluminium Box Manufacturers | Equipment Enclosures Metal | Metal Enclosure Box | Metal Enclosure | Enclosure Box Price | Sheet Metal Manufacturers | Sheet Metal Manufacturing companies | Custom Made Aluminium Boxes | Custom Made Metal Box | Aluminum Sheet Metal Fabrication | Aluminium Sheet Metal Fabrication | Auminium Tool Boxes Made to Order | Custom Metal Enclosures | Custom Stainless Steel Box | Custom Made Aluminum Boxes | Metal Box Manufacturers | Custom Steel Enclosures | Custom Stainless Steel Enclosures | Custom Metal Box | Custom Aluminium Box | Sheet Metal Fabrication Supplier | China Sheet Metal Fabrication | Custom Sheet Metal Fabrication | Sheet Metal Fabrication Services | Metal Manufacturing in China | Aluminum Box Fabrication | Sheet Metal Box Fabrication | Sheet Metal China | Precision Sheet Metal Fabrication | Custom Aluminum Box Fabrication | Custom Metal Box Fabrication