How to Ensure the Appearance of Sheet Metal Chassis Processing Parts is Not Damaged?

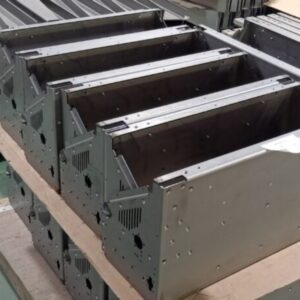

Sheet metal chassis is not an unfamiliar material to everyone, after all, many chassis enclosures are now choosing sheet metal as chassis enclosures. However, the appearance of sheet metal chassis machined parts can be easily damaged during the turnover process of many processes. Therefore, we need to adopt some methods to protect it in order to better ensure that its appearance is not damaged by the outside world. The following are the methods to ensure that the appearance of sheet metal chassis processing parts are not damaged by the outside world:

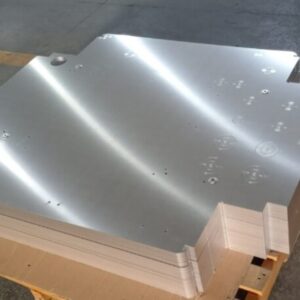

1、A piece of rubber pad can be placed behind the shearing machine according to the length of the shearing machine, placed at an oblique angle and fixed at both ends of the shearing machine, so as to facilitate the sheet metal case processing parts to slide down without touching the surface.

2、After the laser material is formed, it should be placed in the stacking rack of laser material and classified and placed according to the customer and laser parts.

3、After the baked parts come out of the oven, they should be covered with paper or rubber pads. Meanwhile, in the sheet metal chassis processing parts such as racks, they need to be covered around, so as to avoid the sheet metal processing parts from touching the edges during the process of getting on the car or consignment.

4、In addition to the strict requirements of the production process, each sheet metal part requires quality inspection. Not only do we need to strictly control the dimensions of the sheet metal parts according to the drawings, we also need to strictly control the appearance quality of the sheet metal chassis machined parts, so that the appearance does not allow any scratch (flower) marks, and the sheet metal parts that do not match the dimensions are reworked or scrapped. In this way, we can compare whether there are errors in the drawings, whether there are bad operating habits in the manufacturing process, and whether there are possible errors in the manufacturing process, etc.

To sum up, this is the way to ensure that the appearance of the machined sheet metal chassis parts is not damaged by the outside world. In the production process of our sheet metal case processing parts, we can choose suitable methods to ensure that the appearance of the sheet metal case processing parts is not damaged by the outside world according to different actual situations, so that we can effectively avoid the adverse effects brought to the sheet metal processing factory by the good appearance.

Dongguan Jiatong Precision Hardware Products Co., Ltd. is the production of electricity, electronics with aluminum alloy heat sink, intelligent electronic products shell, shielding box, aluminum shell, shell processing, aluminum shell CNC, CNC processing parts, aluminum chassis, industrial control computer chassis, display screen shell, all aluminum shell enterprises. With a group of technically strong and experienced managers and technicians. From mechanical processing to post-surface treatment, advanced technology and techniques are used, with excellent heat dissipation performance of the new generation of products. If you are now looking for a sheet metal manufacturer, a good choice is Dongguan Jiatong Precision Hardware Products Co.

Custom Metal Box Manufacturers | Custom Sheet Metal Enclosures | Custom Aluminum Box | Custom Sheet Metal Boxes | Custom Metal Boxes | Sheet Metal Supplier | Steel Box Manufacturers | Sheet Metal Box Manufacturers | Custom Made Metal Boxes | China Sheet Metal Manufacturer | Outdoor Vending Machine Enclosures | Industrial Machine Enclosures | Metal Enclosures for Electronics | EV Charger Outdoor Enclosure | Outdoor EV Charger Enclosure | EV Charger Enclosure | Custom Aluminium Box | Custom Steel Box | Metal Box Supplier | Metal Enclosure Manufacturer | Sheet Metal Enclosure Manufacturers | Metal Enclosure Box Manufacturer | Metal Enclosure Manufacturer | Aluminium Box Manufacturer | Outdoor Equipment Enclosures | Aluminium Box Manufacturers | Equipment Enclosures Metal | Metal Enclosure Box | Metal Enclosure | Enclosure Box Price | Sheet Metal Manufacturers | Sheet Metal Manufacturing companies | Custom Made Aluminium Boxes | Custom Made Metal Box | Aluminum Sheet Metal Fabrication | Aluminium Sheet Metal Fabrication | Auminium Tool Boxes Made to Order | Custom Metal Enclosures | Custom Stainless Steel Box | Custom Made Aluminum Boxes | Metal Box Manufacturers | Custom Steel Enclosures | Custom Stainless Steel Enclosures | Custom Metal Box | Custom Aluminium Box | Sheet Metal Fabrication Supplier | China Sheet Metal Fabrication | Custom Sheet Metal Fabrication | Sheet Metal Fabrication Services | Metal Manufacturing in China | Aluminum Box Fabrication | Sheet Metal Box Fabrication | Sheet Metal China | Precision Sheet Metal Fabrication | Custom Aluminum Box Fabrication | Custom Metal Box Fabrication