Which Points to Pay Attention to in Aluminum Profile Shell Processing?

Aluminum profile shell is a product made of aluminum alloy, with high flexibility, depth can be cut at will, usually the internal circuit board slot, as long as the circuit board can be inserted directly, no need to fix again, the speed is incomparable to other varieties of shell, the choice of a die-casting molding skills, with waterproof and explosion-proof characteristics. Then the aluminum profile shell processing to pay attention to which points? The following I will introduce you in detail.

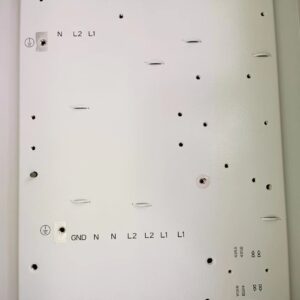

1, for not affecting the number of projects punching as far as possible in the back of the project punching, and even for punching a larger number of products can be considered to do more than one project also to punch the punching row in the back.

2, the aluminum material is soft and the mold is easy to block the material, so in the design of the mold put gap is appropriate to put bilateral material thickness 10% gap, knife straight deep bit to 2MM more appropriate, taper to 0.8-1 ° is appropriate.

3, aluminum profile processing bending molding, because the aluminum material in the bending is easy to produce aluminum chips, will cause point injury ﹑ indentation, aluminum raw materials need to paste PE film, in the case of roller and plating, molding block to polishing hard chrome plating is better.

4, because the aluminum material is brittle, easy to crack, especially in the case of anti-folded edge, so try not to do the pressure line, even if you want to do, but also to make the pressure line a little wider, play a little shallower.

5, all aluminum parts cutter are required to use slow wire cutting, to prevent burrs and falling material is not smooth phenomenon, aluminum parts are easy to produce high temperature, so the hardness of the punch requires more than 60 °, at least with SKD11 material above, not D2 and other poor quality punch.

6. For the stamping parts to be processed after anodizing, if there is a flattening and pushing process of 180°, the products cannot be completely pressed together, which will produce the phenomenon of acid spitting and need to leave a 0.2-0.3MM seam so that the acid can flow out smoothly and timely, so the limit block must be made in this process and the marked mold is higher than the mold.

The above points about aluminum profile shell processing should be noted which points are shared here, aluminum profile shell processing is convenient, high flexibility, high grade, can effectively improve the added value of products, so in the electronics industry has been widely used.

Custom Metal Box Manufacturers | Custom Sheet Metal Enclosures | Custom Aluminum Box | Custom Sheet Metal Boxes | Custom Metal Boxes | Sheet Metal Supplier | Steel Box Manufacturers | Sheet Metal Box Manufacturers | Custom Made Metal Boxes | China Sheet Metal Manufacturer | Outdoor Vending Machine Enclosures | Industrial Machine Enclosures | Metal Enclosures for Electronics | EV Charger Outdoor Enclosure | Outdoor EV Charger Enclosure | EV Charger Enclosure | Custom Aluminium Box | Custom Steel Box | Metal Box Supplier | Metal Enclosure Manufacturer | Sheet Metal Enclosure Manufacturers | Metal Enclosure Box Manufacturer | Metal Enclosure Manufacturer | Aluminium Box Manufacturer | Outdoor Equipment Enclosures | Aluminium Box Manufacturers | Equipment Enclosures Metal | Metal Enclosure Box | Metal Enclosure | Enclosure Box Price | Sheet Metal Manufacturers | Sheet Metal Manufacturing companies | Custom Made Aluminium Boxes | Custom Made Metal Box | Aluminum Sheet Metal Fabrication | Aluminium Sheet Metal Fabrication | Auminium Tool Boxes Made to Order | Custom Metal Enclosures | Custom Stainless Steel Box | Custom Made Aluminum Boxes | Metal Box Manufacturers | Custom Steel Enclosures | Custom Stainless Steel Enclosures | Custom Metal Box | Custom Aluminium Box | Sheet Metal Fabrication Supplier | China Sheet Metal Fabrication | Custom Sheet Metal Fabrication | Sheet Metal Fabrication Services | Metal Manufacturing in China | Aluminum Box Fabrication | Sheet Metal Box Fabrication | Sheet Metal China | Precision Sheet Metal Fabrication