Why is Heat Treatment Necessary in Sheet Metal Processing?

Heat treatment is a process in which a workpiece is heated in some medium, heated to a certain temperature, kept at that temperature for a certain period of time, and then treated by cooling at different speeds. As one of the more important treatment processes in the production of materials, metal heat treatment technology has great advantages compared to other general processing technologies.

Metal in the excavation process has serious instability in its physicochemical properties in use because of its high internal impurities. Through heat treatment processing, it can be effectively purified and its internal purity perfected. Heat treatment technology can also strengthen its quality improvement and optimize its actual use function. Therefore, the application of heat treatment is often indispensable in sheet metal processing.

When the workpiece is heated and reaches a certain temperature, different holding times are applied depending on the size of the workpiece and the material, and then slow cooling is performed, which is annealing. The main purpose of annealing is to reduce the hardness of the material and improve the plasticity of the material, so that it can be easily processed after sheet metal processing is a kind of processing technology that uses machine tools and equipment to process the parts.

In summary, these are the reasons for heat treatment in sheet metal processing. In the process of sheet metal processing, in addition to the reasonable selection of materials and various forming processes, heat treatment process is often essential. After all, heat treatment generally does not alter the shape and overall chemical composition of the workpiece, but rather gives or improves the use of the workpiece by altering the microstructure inside the workpiece, or by altering the chemical composition of the surface of the workpiece. Thus, by heat treatment, we can improve the intrinsic quality of the sheet metal processing parts.

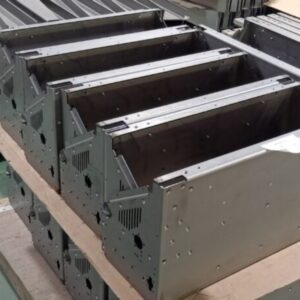

Custom Metal Box Manufacturers | Custom Sheet Metal Enclosures | Custom Aluminum Box | Custom Sheet Metal Boxes | Custom Metal Boxes | Sheet Metal Supplier | Steel Box Manufacturers | Sheet Metal Box Manufacturers | Custom Made Metal Boxes | China Sheet Metal Manufacturer | Outdoor Vending Machine Enclosures | Industrial Machine Enclosures | Metal Enclosures for Electronics | EV Charger Outdoor Enclosure | Outdoor EV Charger Enclosure | EV Charger Enclosure | Custom Aluminium Box | Custom Steel Box | Metal Box Supplier | Metal Enclosure Manufacturer | Sheet Metal Enclosure Manufacturers | Metal Enclosure Box Manufacturer | Metal Enclosure Manufacturer | Aluminium Box Manufacturer | Outdoor Equipment Enclosures | Aluminium Box Manufacturers | Equipment Enclosures Metal | Metal Enclosure Box | Metal Enclosure | Enclosure Box Price | Sheet Metal Manufacturers | Sheet Metal Manufacturing companies | Custom Made Aluminium Boxes | Custom Made Metal Box | Aluminum Sheet Metal Fabrication | Aluminium Sheet Metal Fabrication | Auminium Tool Boxes Made to Order | Custom Metal Enclosures | Custom Stainless Steel Box | Custom Made Aluminum Boxes | Metal Box Manufacturers | Custom Steel Enclosures | Custom Stainless Steel Enclosures | Custom Metal Box | Custom Aluminium Box | Sheet Metal Fabrication Supplier | China Sheet Metal Fabrication | Custom Sheet Metal Fabrication | Sheet Metal Fabrication Services | Metal Manufacturing in China | Aluminum Box Fabrication | Sheet Metal Box Fabrication | Sheet Metal China | Precision Sheet Metal Fabrication | Custom Aluminum Box Fabrication | Custom Metal Box Fabrication